Roll-through rack

Flow racks not only provide compact storage and save space, but also contribute to a well-organized warehouse. They are ideal for part kitting and lean applications where flow, FIFO, and Kanban are essential. Thanks to their modular design, these racks are easy to adapt to your specific needs.

Didn’t find what you’re looking for among our standard solutions? We also build custom setups using our modular construction system.

Customised

Need a specific size or configuration? Mobile or stationary? No problem—thanks to the modular concept.

Space-saving and structure

The racks provide compact and well-organized storage for your materials.

FIFO en kanban

Guarantees First In, First Out. Ideal for Kanban management.

ESD safe

Ask about our ESD-safe solutions.

Types of flow racks

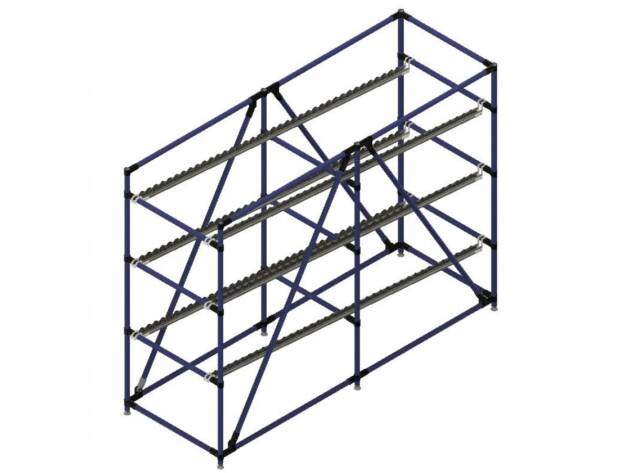

- Fixed

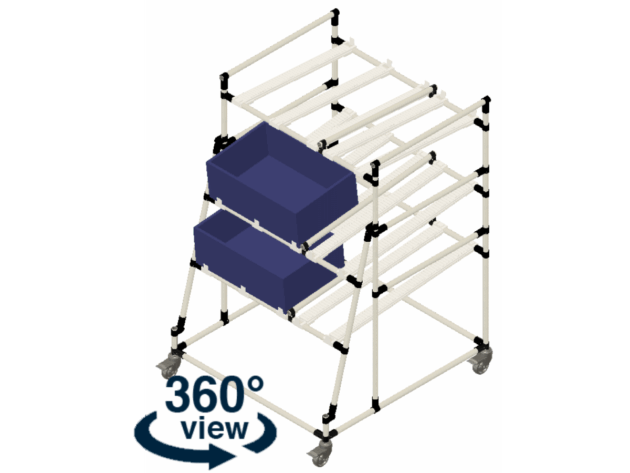

- Mobile

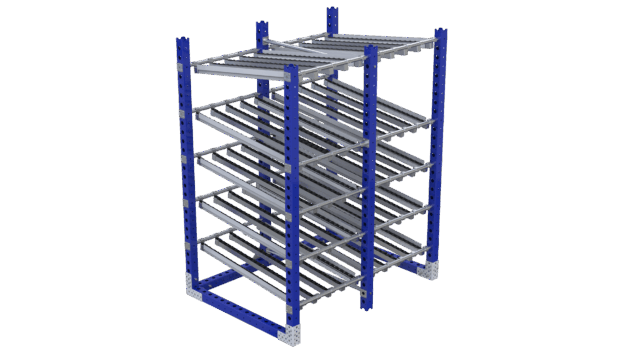

- Angled discharge

- Stepped design

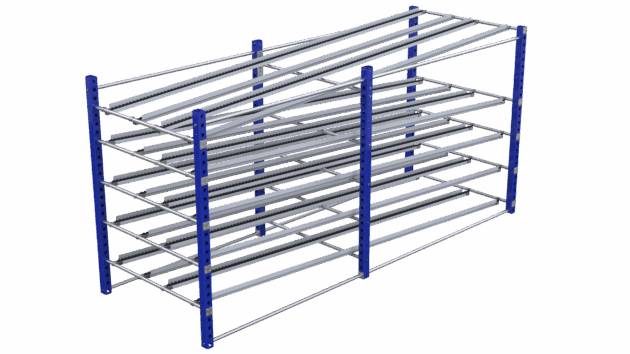

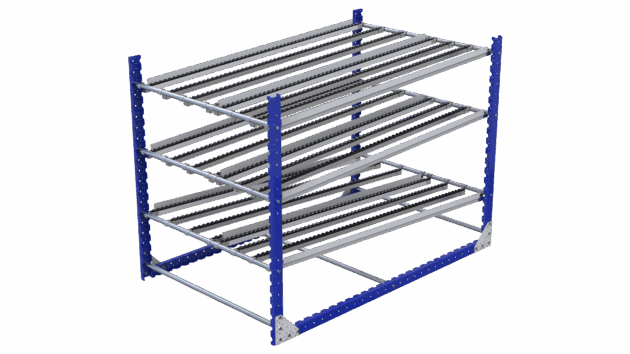

Fixed flow racks

If you need flow racks or roller racks with a fixed location, fixed racks are preferred. These come with adjustable feet or feet that can be anchored to the floor.

The number of rack levels is freely selectable, and they are also easy to adjust in height. A return for the bins across the full width or limited to one location? Label holders, two or more roller conveyors per bin, guides, … Just choose. The possibilities are almost unlimited.

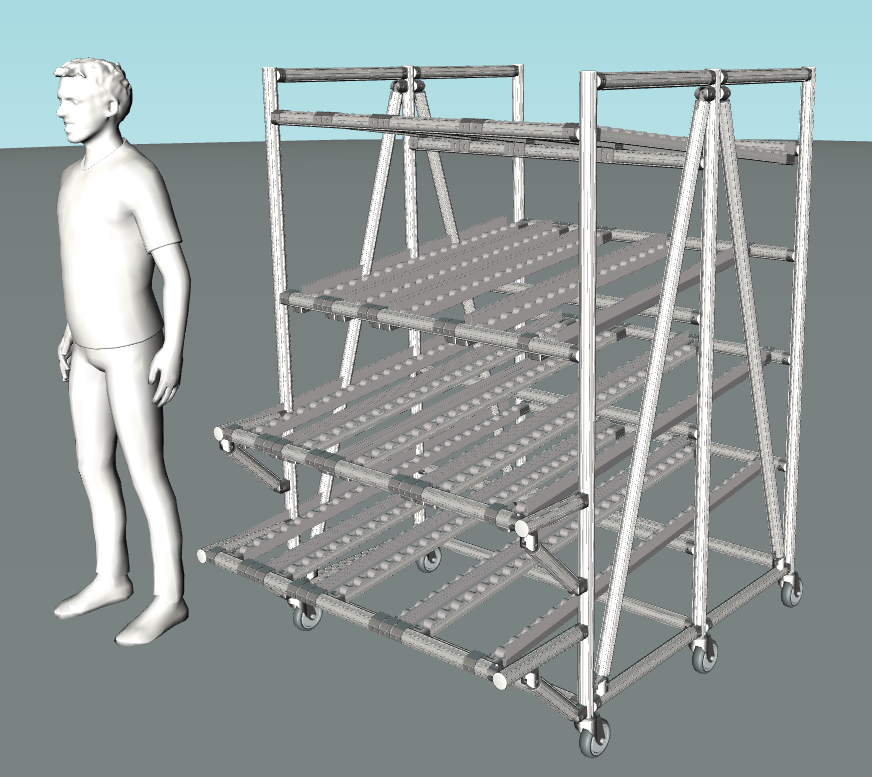

Mobile roller racks

“If you need flow racks or roller racks where the location is not fixed or flexibility is important, our mobile racks are the best choice. These flow racks are equipped with top-quality wheels selected based on the required load capacity.

The number of rack levels is freely selectable, and they are also easy to adjust in height. A return for the bins across the full width or limited to one location? Label holders, two or more roller conveyors per bin, guides, … Just choose. The possibilities are almost unlimited.

Angled discharge

In a standard flow rack, the bins are positioned at an incline of about 5°. Depending on the number of levels and the size of your parts, more gripping space may be needed. This can be achieved with an angled dispensing section. If that’s still not enough, a stepped design is the solution you’ll need.

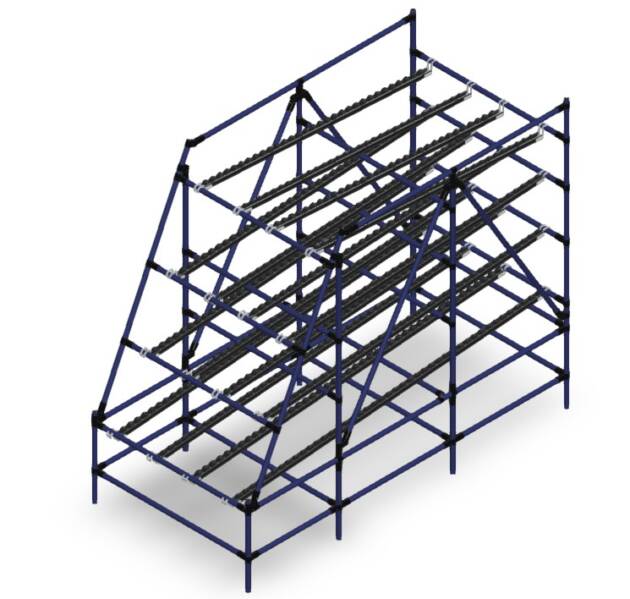

Stepped design

To make the parts more visible and the (larger) parts easier to grasp, a flow rack with a stepped design is preferred. If that still doesn’t provide enough space, adding an angled dispensing section will certainly help.

Showing all 10 results