Roller conveyors

The LEAN philosophy aims to limit or avoid transport. However, if you do need it, a gravity or automatic roller conveyor can be ideal for doing this as efficiently as possible. Our roller conveyors make it easy to move boxes, crates, pallets, etc.

If you cannot find what you are looking for among our standard solutions, we can build a customised solution using our modular construction system.

Customised

Need a specific size or configuration? Mobile or stationary? No problem—thanks to the modular concept.

ESD safe

Ask about our ESD-safe solutions.

Add-ons

Add the desired accessories, such as stoppers, guides, wheels, and more.

Cleanroom

“A conveyor belt can also be useful in a cleanroom. Ask us about it.

ROLLER CONVEYOR TYPES

- Pipe & joint

- Aluminium

- Heavy duty

- Gravity

- curved roller conveyors

- mobile

- ESD

- powered conveyors

- AGV/AMR

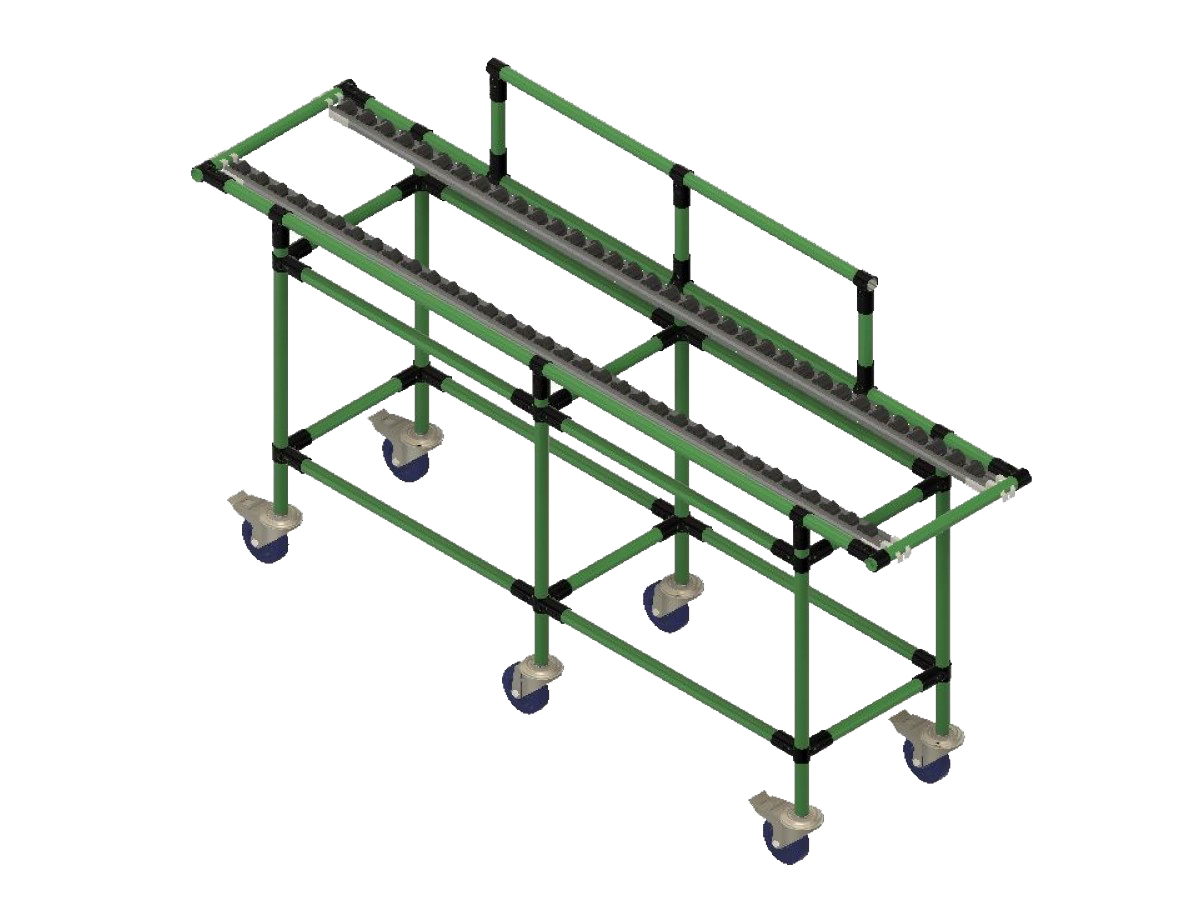

pipe & joint roller conveyors

With our modular pipe & joint system, we design and build custom roller conveyors. The dimensions can be freely chosen, as well as the type of roller conveyor, so that we can provide the ideal solution for your products. Would you like shelves below or above the roller conveyor, or a top structure with perforated panels, lighting, etc.? Everything is possible.

Some advantages of the pipe & joint system:

– Developed in Japan to promote continuous improvement in every company

– Fast implementation

– Quick learning curve if you want to work on it yourself

– Ideal for prototype construction

– Adaptable and reusable

– Unlimited possibilities

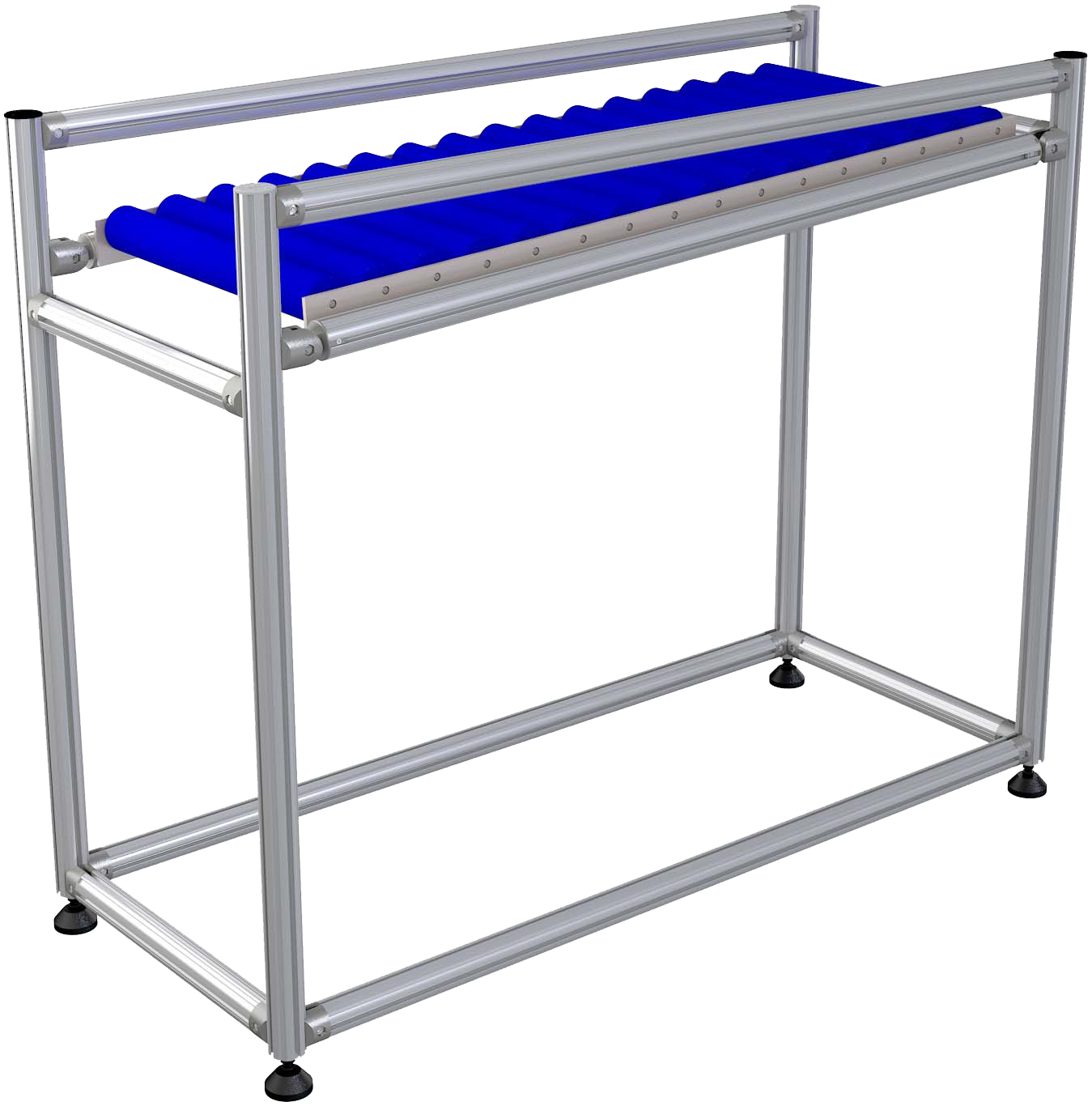

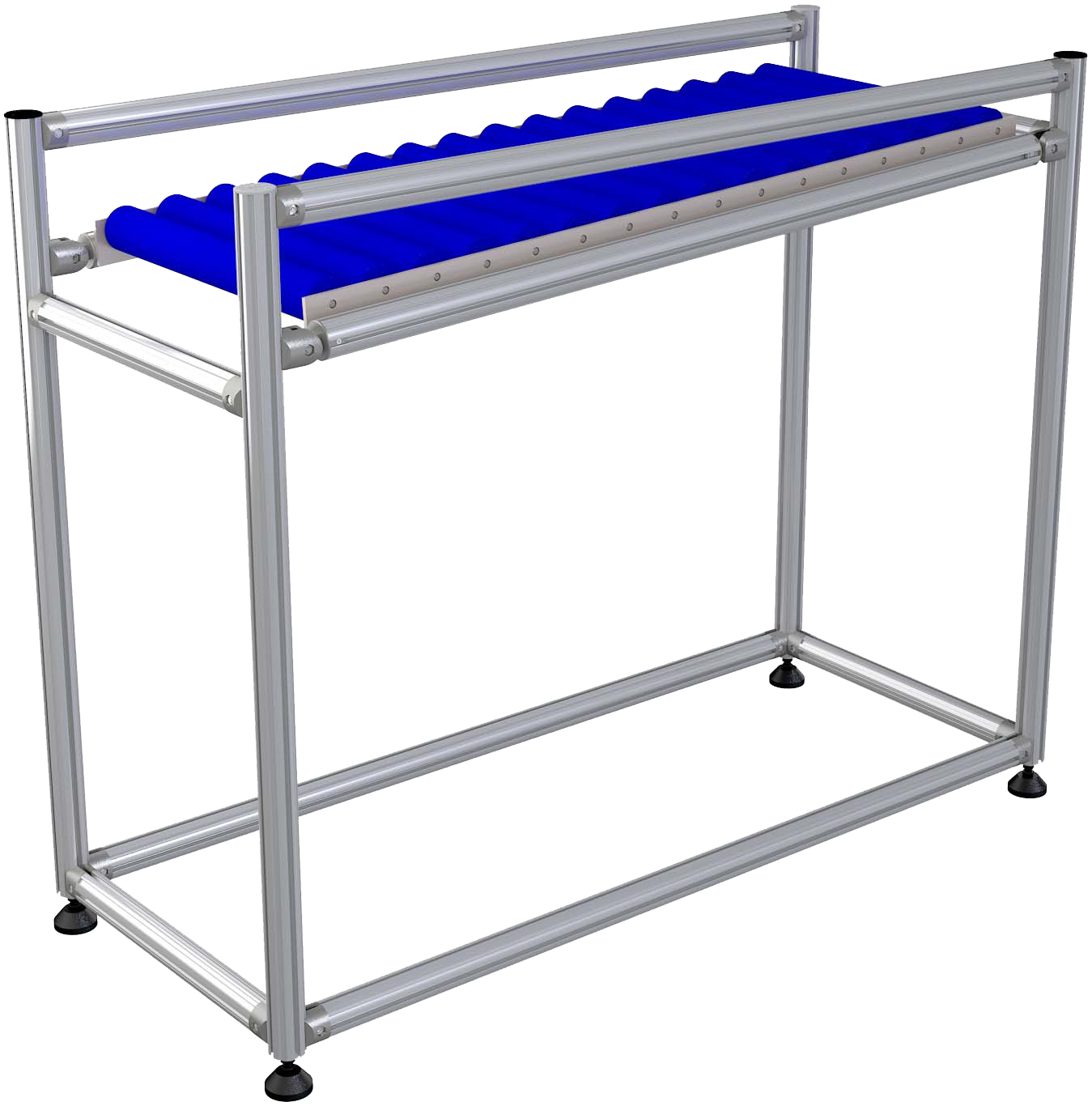

aluminum roller conveyors

With our aluminum pipe & joint system, we design and build custom roller conveyors. The dimensions can be freely chosen, as well as the type of roller conveyor, so that we can provide the ideal solution for your products. Would you like shelves below or above the roller conveyor, or a top structure with perforated panels, lighting, etc.? Everything is possible. Even height adjustability of your roller conveyor is an option, for example, a conveyor between two height-adjustable tables.

Some advantages of the aluminum system:

– Robust and attractive profile of 40mm or 60mm with only 4 connectors

– Fast implementation

– Quick learning curve if you want to work on it yourself

– Ideal for prototype construction

– Adaptable, reusable, and recyclable!

– Unlimited possibilities

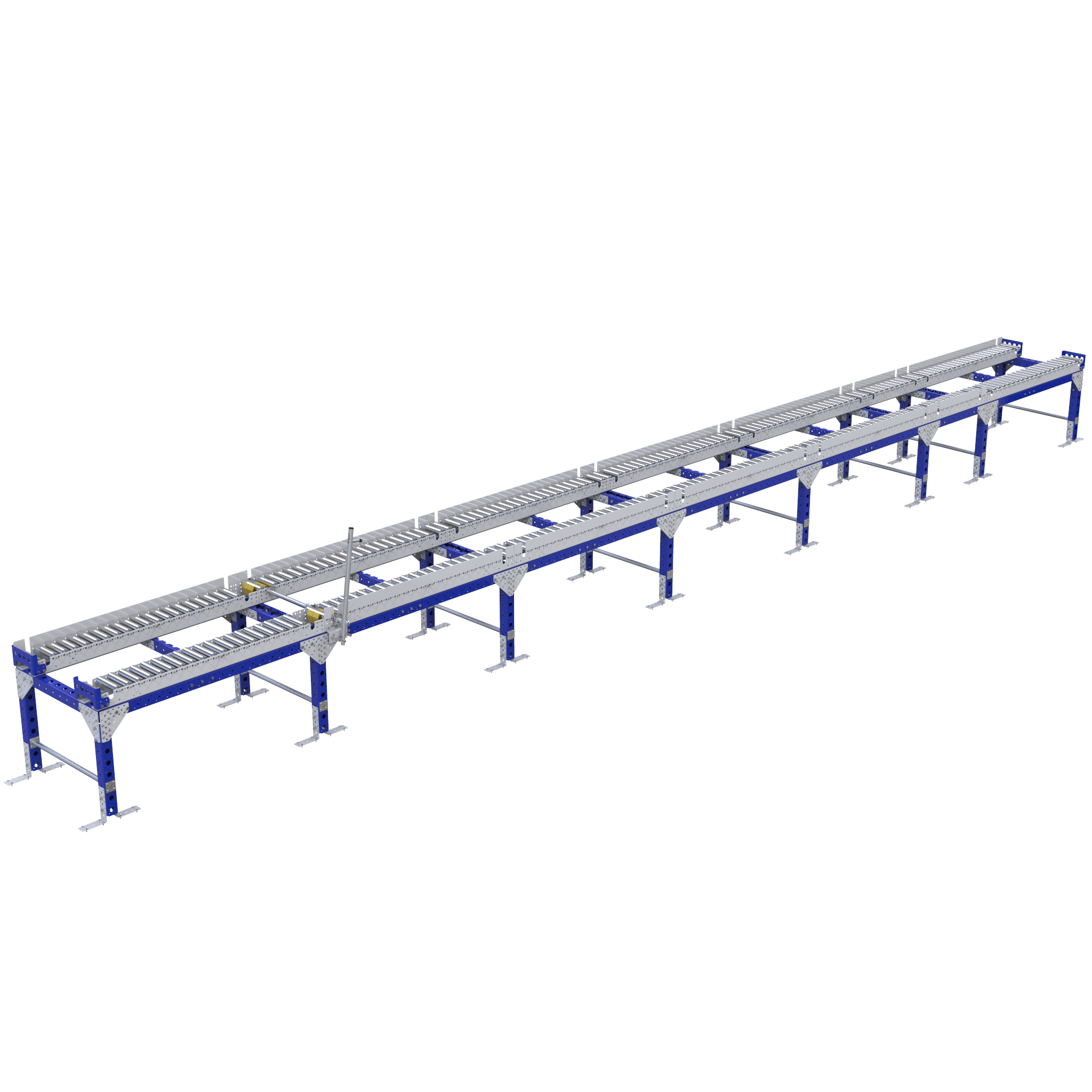

heavy-duty roller conveyors

In many warehouses, heavily loaded pallets are also in circulation. For transporting these pallets, we offer roller conveyors with a load capacity of up to 4,000 kg. Here too, we benefit from the modular system: adaptable in terms of dimensions, gravity or powered, free-flow or driven, integration with AGVs and AMRs, etc.

Endless possibilities. Feel free to contact our specialists.

gravity roller conveyors

A gravity roller conveyor is an ideal solution when bins or pallets need to be moved over a short distance. Thanks to the force of gravity provided by “Mother Nature,” no energy is required for this automatic transport, a nice saving on your energy bill. Also, consider how simple adjustments (e.g., shortening, lengthening, etc.) are, which are far less straightforward with a powered roller conveyor.

Our gravity roller conveyors can be made in both pipe & joint or aluminum. Our systems allow the incline to be easily adjusted according to the weight of your products.

Here as well, the dimensions can be freely chosen, as well as the type of roller conveyor, so that we can provide the ideal solution for your products. Would you like shelves below or above the roller conveyor, or a top structure with perforated panels, lighting, etc.? Everything is possible.

For longer distances, we of course have AGVs, AMRs, as well as powered roller conveyors.

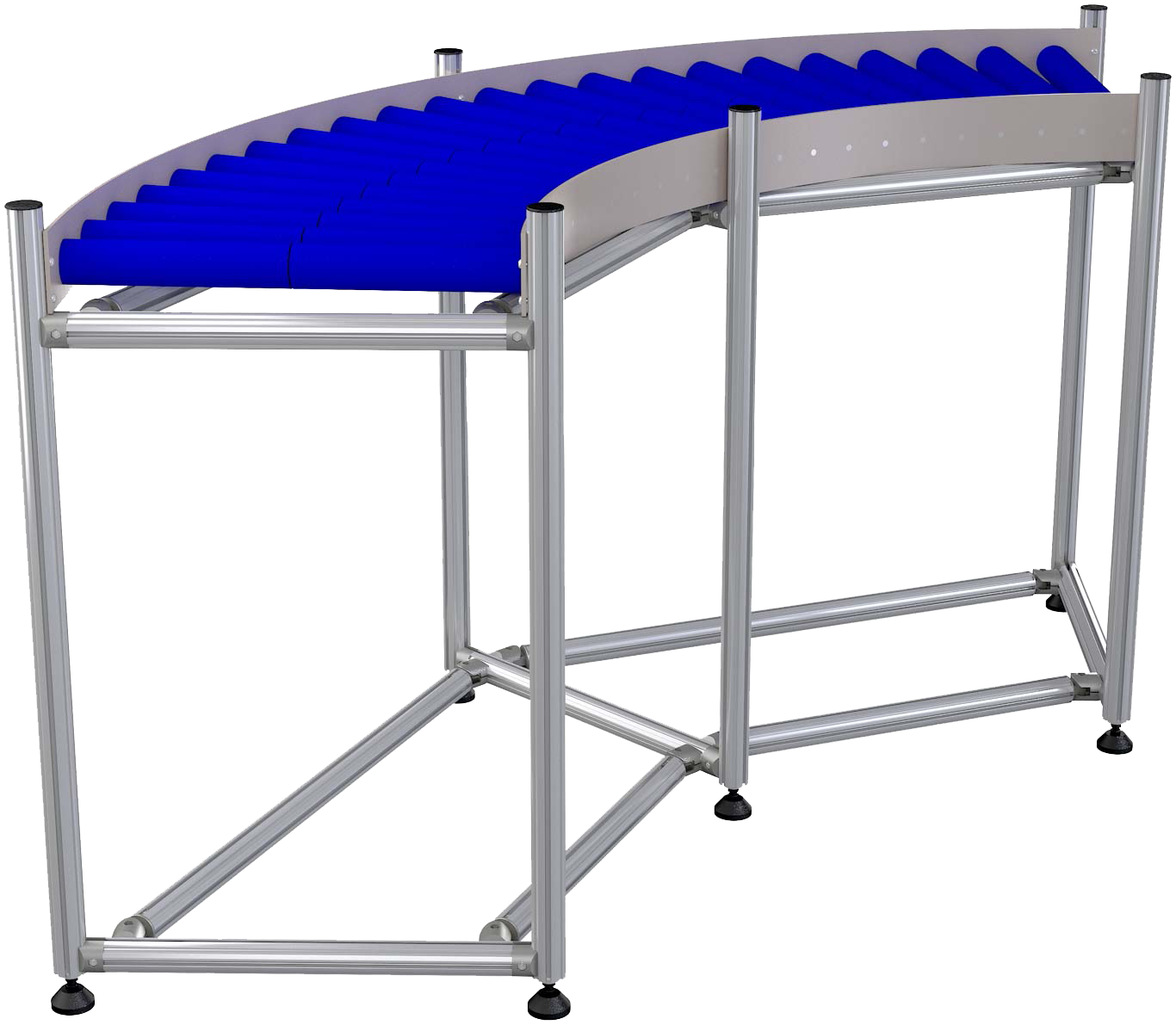

curved roller conveyors

A roller conveyor curve is an essential part of a roller conveyor, used to change the transport direction of goods, often in a 45° or 90° bend. The positioning and shape of the rollers are crucial to allow the goods to move smoothly through the curve. You can choose between a standard free-flow roller curve, a gravity curve, or a powered curve.

Need a specific width or height? Would you like shelves below or above the roller conveyor, or a top structure with perforated panels, lighting, etc.? Everything is possible.

mobile roller conveyors

Is it important for you that the roller conveyor is mobile so it can be moved occasionally? No problem, we equip them with wheels suited to the conveyor’s load capacity. With our lifting casters, we ensure even greater stability while still providing mobility when needed.

The dimensions can be freely chosen, as well as the type of roller conveyor, so that we can offer the ideal solution for your products. Would you like shelves below or above the conveyor, or a top structure with perforated panels, lighting, etc.? Everything is possible.

ESD roller conveyors

In certain environments, it is essential to be able to work in an ESD-safe manner. At LeanFlow, you will find suitable ESD roller conveyors. These are available in both pipe & joint and aluminum. And of course, they are also height-adjustable.

Here as well, the dimensions can be freely chosen, as well as the type of roller conveyor, so that we can offer the ideal solution for your products. Would you like shelves below or above the roller conveyor, or a top structure with perforated panels, lighting, etc.? Everything is possible.

powered conveyors

A gravity roller conveyor is an ideal solution when bins or pallets need to be moved over a short distance. For longer distances, we of course have AGVs, AMRs, as well as powered roller conveyors.

Powered roller conveyors, of course, also involve sensors, motors, buttons, and PLCs. No problem for our automation engineers!

AGV/AMR with roller conveyor

By combining the use of AGVs or AMRs with roller conveyors, we create tremendous flexibility. We move boxes, bins, and pallets throughout your warehouse and ensure automatic transfer to flow racks and fixed roller conveyors. In this way, transport becomes fully automated and your employees can focus on their value-adding activities.

Feel free to contact our automation engineers to help think along with your challenges!

Showing the single result