Packing lines

If you have a large volume of products to package, then a packing line is the right solution! Gravity or powered roller conveyor, height adjustability, ESD-safe design, etc. We ensure an efficient and ergonomic packing and shipping flow.

Customised

Need a specific size or configuration? Mobile or stationary? No problem—thanks to the modular concept.

Efficiency

A roller conveyor eliminates walking distances, which greatly improves the efficiency of the packing process.

ESD safe

Please enquire about our ESD-safe solutions.

Add-ons

Add the desired accessories such as screen and keyboard holders, drawers, scanner holder, wheels, etc.

Type of packaging lines

- Pipe & joint

- Aluminium

- “With attached flow racks

- Conveyor belt with packing tables

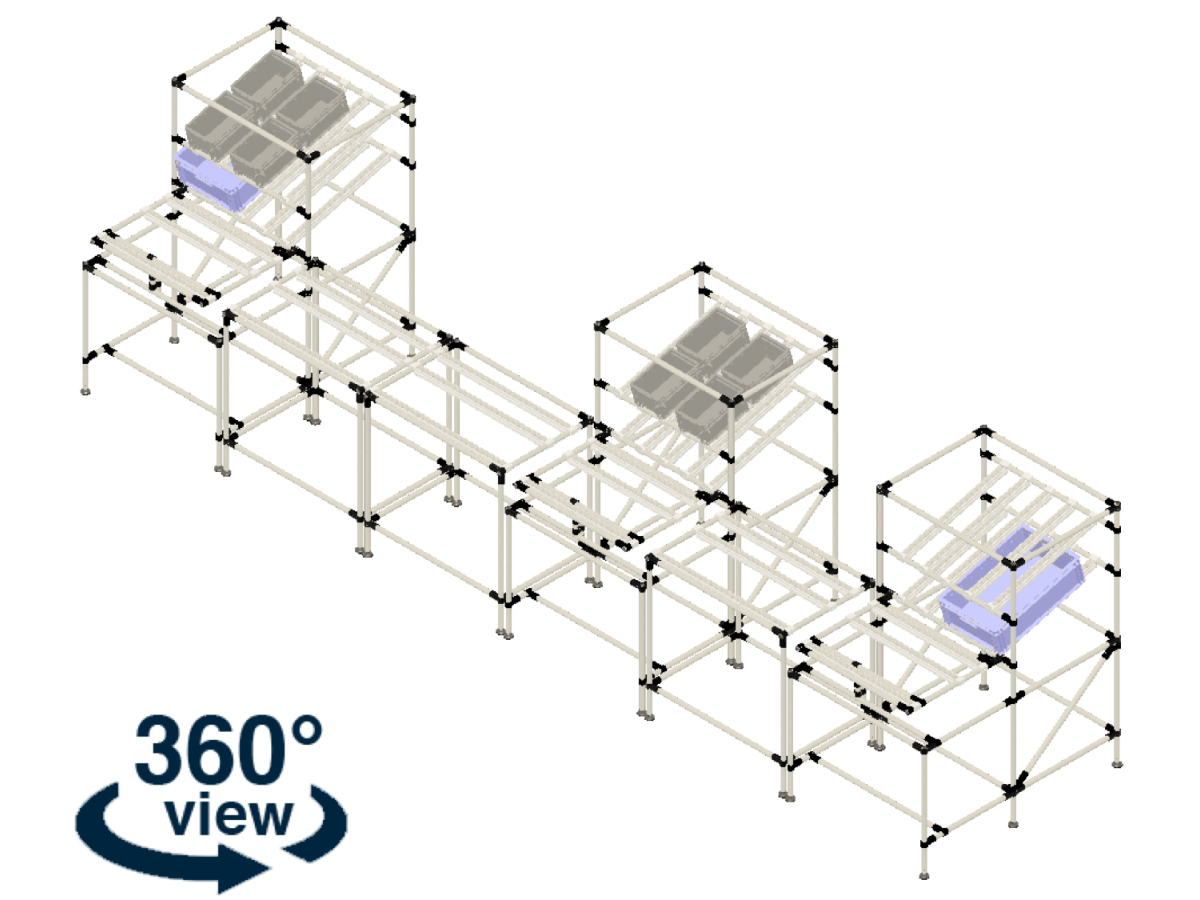

Pipe & Joint packing lines

With our modular Pipe & Joint system, we design and build custom packing lines. The dimensions can be freely chosen, as well as the type of roller conveyor, allowing us to create the ideal solution for your products. Do you want shelves below or above the line, or an overhead structure with a flow rack for goods, pegboards, lighting, etc.? Everything is possible.

Some advantages of the pipe & joint system:

– Developed in Japan to promote continuous improvement in every company

– Fast implementation

– Quick learning curve if you want to work on it yourself

– Ideal for prototype construction

– Adaptable and reusable

– Unlimited possibilities

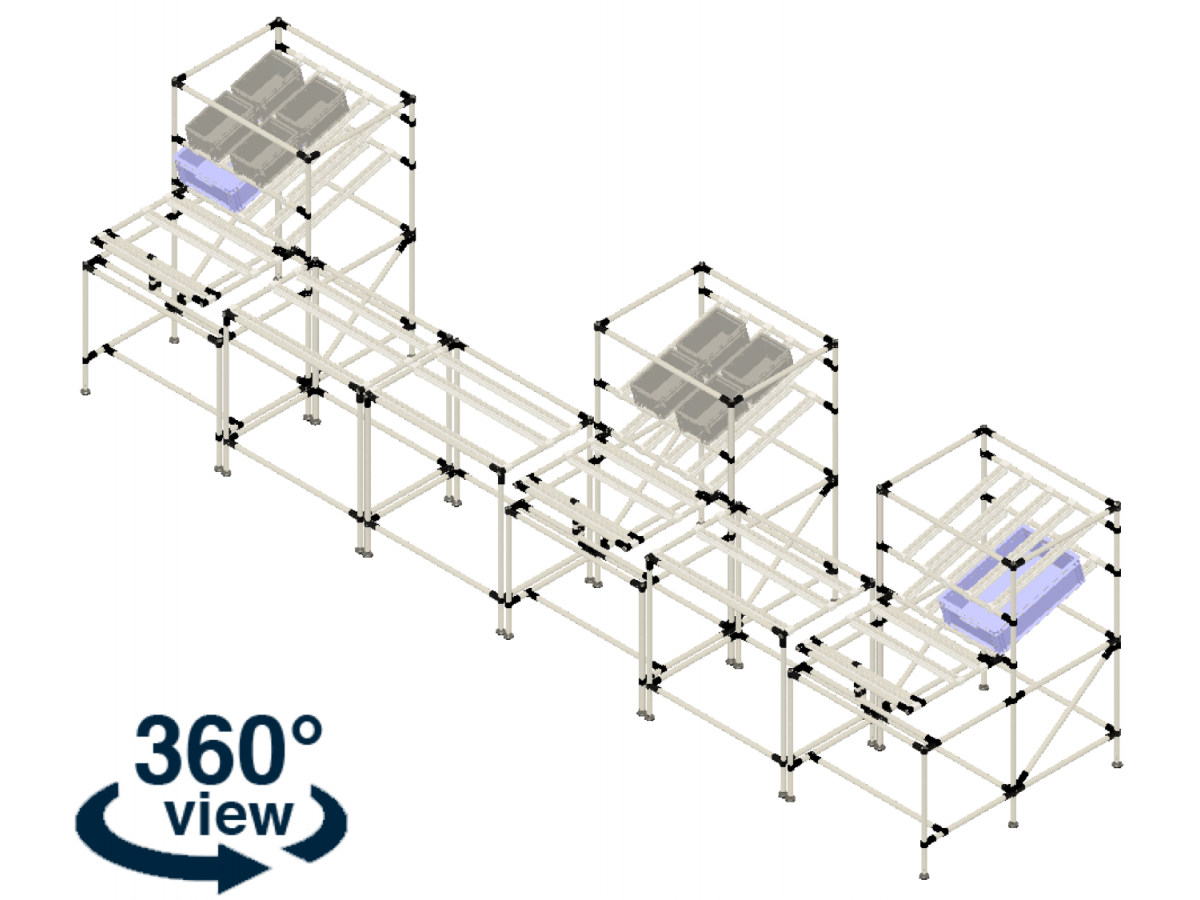

Aluminum packing lines

With our aluminum Pipe & Joint system, we design and build custom packing lines. The dimensions can be freely chosen, as well as the type of roller conveyor, so we can create the ideal solution for your products. Do you want shelves below or above the line, or an overhead structure with flow rack for goods, pegboards, lighting, etc.? Everything is possible

Even height adjustability of your packing line is possible.

Some advantages of the aluminum system:

– Robust and attractive profile of 40mm or 60mm with only 4 connectors

– Fast implementation

– Quick learning curve if you want to work on it yourself

– Ideal for prototype construction

– Adaptable, reusable, and recyclable!

– Unlimited possibilities

Packing line with attached flow racks

If you have a limited variety of parts but a high volume of packing work, a packing line with attached flow racks is a good choice.

Parts can be easily picked from ergonomically arranged flow racks. These can be replenished from the back so that the packing process is not interrupted.

Boxes are filled with the correct parts as they move along the flow racks. At the end of the flow, we provide a box closer.

These packing lines and flow racks can be built using either pipe & joint or aluminum.

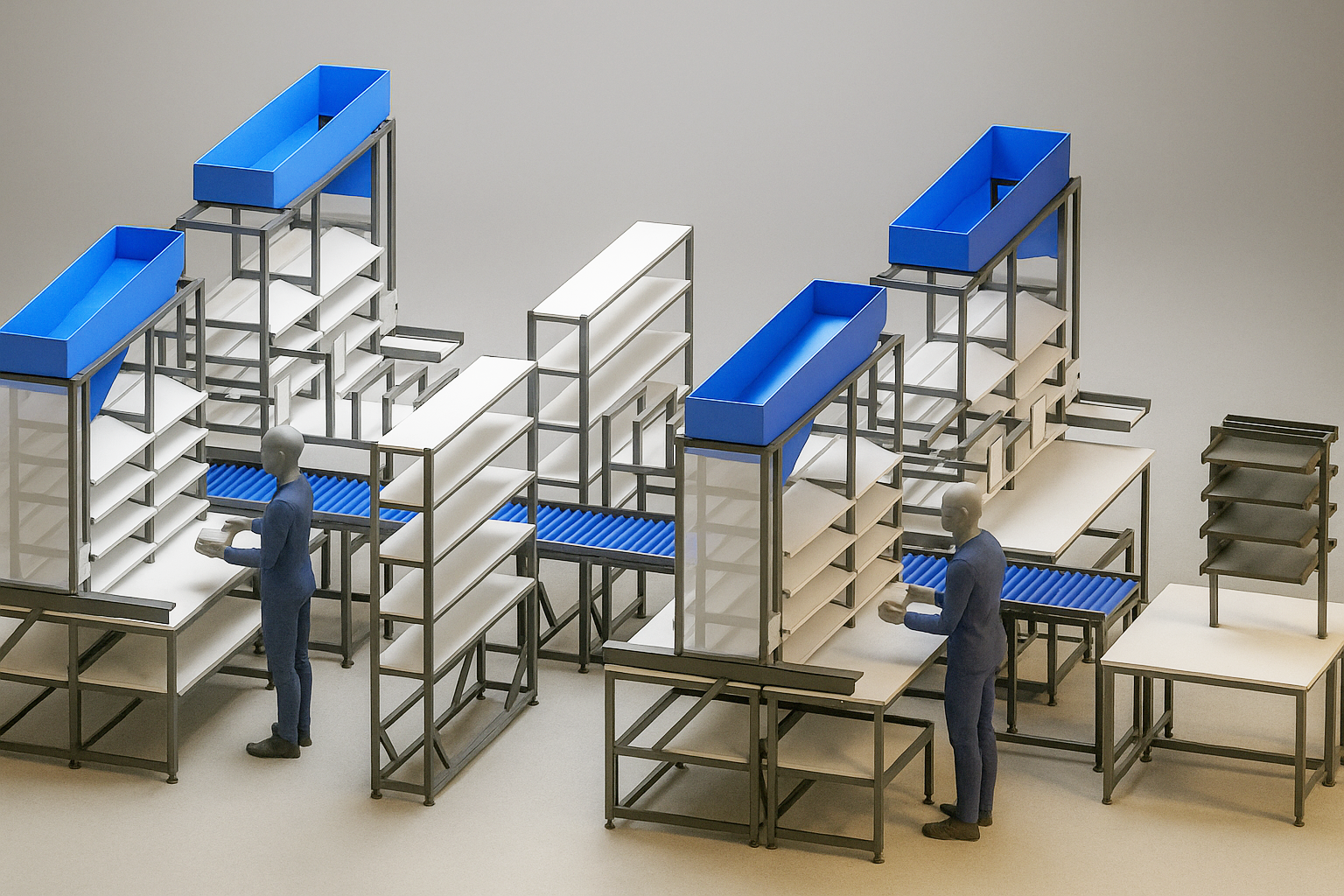

Conveyor belt with packing tables

If you have a larger variety of parts and a high volume of packing work, a conveyor with packing tables is a good choice.

In a preceding process, the parts are collected from flow racks or from an automated warehouse. These collected parts are transported via a gravity or powered conveyor to a packing zone. There, multiple packing tables are set up, where operators can quickly and efficiently pack the collected parts. Each table is equipped with all necessary equipment, such as a screen, printer, scanner, bubble wrap roll, film cutter, and a top structure with dividers for different types of cardboard, etc.

These conveyors and packing tables can be built using either pipe & joint or aluminum. Height adjustability ensures the best possible ergonomics during packing.

No results